B - 13, Sipcot industrial estate,

Gummidipoondi, Chennai.

mnellaiyahrollingmill@gmail.com

(+91) 99625 55526

Why MCR TMT?

Founded in 2021, Nellaiyah Rolling Mill is a leading integrated steel manufacturer based in Gummidipoondi, Chennai. Our mission is to provide construction-grade steel solutions with uncompromising quality and exceptional value. Our Brand, MCR TMT BARS, symbolizes resilience, robustness and trust through reliable products. Over the years, it has earned a stellar reputation among civil engineers, architects and builders for delivering outstanding strength. Today, we have a production capacity of 90,000MTPA to effectively meet rising demand. By embracing cutting-edge technology and advanced global systems, we have established ourselves as the driven force of progress in the industry. This has allowed Nellaiyah Rolling Mill to scale new heights as one of Tamil Nadu's premier steel companies. Our journey of transforming skylines is a reflection of collaborative excellence across all levels.

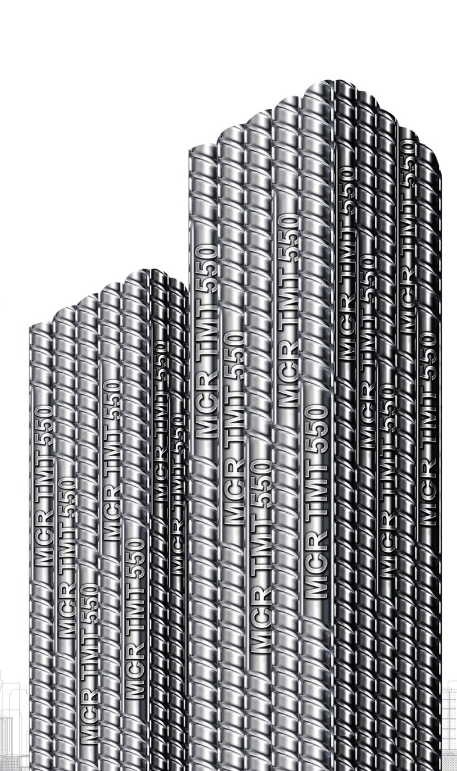

MCR TMT 550 & 550D

• MCR TMT 550 & 550D is a uniquely produced product of our company that meets the quality standards set by BIS specifications and complies with BIS and GERMAN Standards.

• The manufacturing process of MCR TMT 550 & 550D ensures a combination of strength and ductility that exceeds the minimum limits specified by Bureau of Indian Standards

• MCR TMT 550 rebars are available in various sizes (8, 10, 12, 16, 20, 25, and 32 mm) through our retail and distribution network across South India.

• MCR TMT 550 & 550D is supplied in convenient pre-packed bundles with a fixed number of pieces per bundle, organized by size for ease of use.

• Each bundle contains MCR TMT 550 & 550D rebars, providing customers with a reliable and efficient solution for their construction needs in South India.

• Our commitment is to deliver MCR TMT 550 & 550D that meets the highest quality standards and ensures the durability and strength required for construction projects.

What we do

HIGHEST QUALITY ASSURANCE

POWERFUL BONDING

SUPERIOR STRENGTH

SEALED PACKAGING

COST EFFECTIVE

QUALITY

We maintain an unwavering commitment to quality throughout our manufacturing process, from sourcing raw materials to delivering finished goods, to guarantee utmost customer satisfaction. The essential value-added components of our TMT Bar are exclusively obtained from a highly dependable source, ensuring the chemical composition of the metal remains synchronized with the parent Fe. Each metal possesses its own distinct qualities and behaves differently in various conditions and applications. Achieving the optimal blend and quality is imperative to produce TMT bars of the highest caliber.

FINISHED GOODS